ACE CLEARWATER: POISED FOR THE FUTURE

Gary Johnson, Vice President

“We break the misconceptions people have about manufacturing — ours is an industry where we do really cool creative stuff everyday.”

Inspiring Generations

ACE Clearwater is expanding its capabilities with state-of-the-art technologies that improve its customer service and attracts new generations to the manufacturing industry.

By Janice Hoppe

ACE Clearwater is investing $1.5 million per year upgrading equipment, training their workforce, and exploring new tech that it hopes will attract a “next generation” of manufacturing worker. “Our main focus is trying to find new talent,” Vice President Gary Johnson says. “We want to break the misconceptions about manufacturing because it is an industry where you can do really cool stuff. Manufacturing is still the backbone of this country.”

To meet growing demand, ACE Clearwater has added six large machining centers to bring more in-house control to its tooling and machine shop. The company acquired a nine-foot Faro Arm with laser scanning capabilities for portable inspection of dies and large assemblies, which improves production flow. Two new drop-hammers were also installed to increase capacity at their metal forming facility.

Most recently, ACE Clearwater purchased a small $55,000 3-D printer. Engineers at the company were encouraged to experiment with the new technology. They were soon able to replace aluminum used to make brackets and clamps with ballistic plastic. The weld fixtures are now a combination of plastic and metal. ACE Clearwater has since upgraded to a larger $600,000 3-D printer that prints 44” and larger parts straight from a customer’s CAD file. “We load the file into the printer and go. It runs overnight without any need to monitor,” Johnson explains. “It’s worked out really well.”

ACE specializes in welding, machining, drop-hammer forming, hydro-forming and precision CNC milling for the aerospace and power generation markets. Now they set themselves apart by providing printed miniature models to ensure assemblies are manufactured best. “The Honeywell e-ductor on the Boeing Triple Seven is a big, big program,” Johnson adds. “We create small versions of the part and can discuss concerns we may have about it,” he adds. “Afterwards, engineers want the miniature parts to put on their desks. It’s a really good marketing tool because people can physically interact with it. It’s really cool.”

The Right Technology

“Technology is what we come to play with,” Johnson says. “Additive manufacturing is here to stay. It’s a game-changer. Pretty soon we will be able to make drop-hammer tools out of plastic. What used to take eight weeks creating fiberglass and plaster forms can now be printed in 24 to 48 hours. And on top of that, they are even better – more accurate then ever. That’s what everyone wants.”

For a long time, price was the main focal point for customers until they realized they were buying problems – not parts, Johnson explains. Quality and delivery have become the frontrunners in terms of customers’ demands. “An 80% quality acceptance rate is no longer being accepted,” Johnson explains. “It’s 98% and you start getting penalized for anything under that. Sure we have lost jobs to competitors, but we just tell that customer to let us know when they want to bring it back. Ninety-nine percent of the time it comes back to us. Because it’s not just about price anymore; it’s about performance and quality. “

“We don’t have a standard product, all of our work is custom,” Johnson says. “We are building different assemblies every day. A lot of customers have retired from the aerospace industry and the new buyers haven’t been around long enough to have a firm understanding of manufacturing. They want to know everything all the time to feel confident. The RFID gives them access. We are kind of excited about that whole thing.”

Fun with Tools

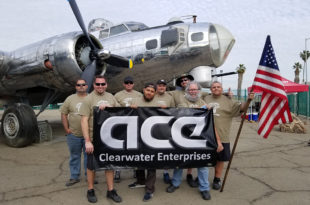

Although ACE Clearwater is focused on attracting new talent with state-of-the-art equipment right now, it is also working to make manufacturing cool to younger generations. “We bring a lot of kids through the facility on Manufacturing Day in October,” Johnson says. “We had nearly 400 people participate last year. We operate our 3-D printers, use motion technology so kids can manipulate CAD files in mid-air, show them computer-driven laser cutting machines… and we can really see the light bulbs going off. Our welding equipment supplier brings in a virtual welding trainer. The kids love it.”

To build upon this enthusiasm, ACE Clearwater donates equipment to schools and speaks to students about the industry. They also reach out to high school students to suggest a fulfilling career path in manufacturing; to encourage trade schools and city colleges as alternatives to other options. This education extends to their shop floor. “We want a smart shop employee. We fully support their self-improvement,” he says. “Our employees are encouraged to go back to school an earn more advanced certification. We pay for all of this; they just have to give their time,” Johnson says. “Our people have taken advantage of this, gone through training and gotten certified. They come back smarter and realize they also received a raise. Everybody wins. The education program has snowballed.”

ACE Clearwater also goes the extra mile to recruit new skilled workers. It even searches outside its hometown of Torrance, California – all the way into Texas, Colorado and Kansas. “It’s a constant struggle because there is a lot of work, with more on the way,” Johnson says. “The commercial aerospace market is exploding and we have a promise and commitment to make sure we deliver. And deliver well. That’s why we say ACE stands for Attitude Committed to Excellence.”