ACE INCORPORATES ADDITIVE MANUFACTURING

The Latest Technology Merges with Traditonal Approaches to Streamline Manufacturing Process.

November 10, 2014

November 10, 2014

Two years ago, ACE President Kellie Johnson realized that the development of additive manufacturing had come to pass — and that ACE better get up to speed with an industry that would have a direct impact on the entire manufacturing community.

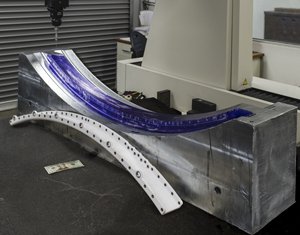

Starting with a medium-size Fortus 240mc by Stratysis, engineers at the company began to experiment with 3D printing, just to learn its traits. In a year’s time, the company was regularly using the device for production models and combining 3D-printed objects with traditionally manufactured parts to create tools and fixtures for welding. Driven by powerful 3D engineering software, these machine brought to life scaled-down versions of complex parts making improvements with customers’ engineers dramatically better.

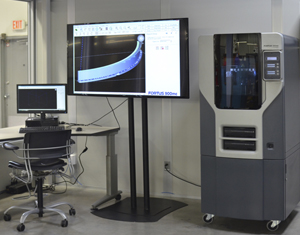

In 2015, ACE acquired a Fortus 900mc large format printer. The larger bay enabled engineers to make substantially bigger fixtures, with size-retaining properties. These fixtures are now printed and used throughout the manufacturing floor for in-process inspection and for precision placement of holes and radius checks. An entire Lab room was constructed in our Torrance North facility, and is frequently used to demonstrate this capability during tours by our business colleagues and  associates.

associates.