EXTRAORDINARY WOMEN, MANUFACTURING BUSINESS LEADERS – KELLIE JOHNSON

Women manufacturing business leaders do not get their due. Creating jobs, innovating next generation technologies, competing on a global scale, they are launching us into the future.

By Drew Greenblatt

President, Marlin Steel

Published in Inc. Magazine February 7, 2017

A: I believe there is something really important about making things. It’s the classic American notion of self-reliance; freedom, prosperity, security. Too many people have an outdated perception of manufacturing. We need to make the case that manufacturing is not a relic of the past but a vital element of a prosperous future plus at ACE Clearwater we make some really cool things. If it flies our parts are on it! When jobs are the number one issue – manufacturing is a known solution, it’s not a bubble. Innovation is the lifeblood of manufacturing but without manufacturing innovation is just a good idea.

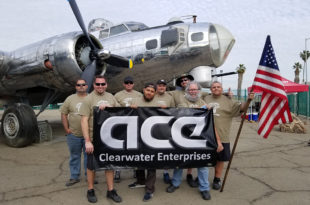

A: ACE Clearwater is a supplier to the aerospace industry and we build to our customer’s data and specifications. Close proximity to our customer’s has given us a competitive advantage. We have become partners not just a supplier.

A: My fear is my customer’s will migrate to where the most robust infrastructure and supply chains exist to conduct business. While other countries have been transforming their business environments to accelerate growth we’ve added to our cost burden, erected new regulatory barriers and created an environment of uncertainty and uncertainty is a killer for a capital intensive industry like manufacturing. We need stable, predictable, pro-growth policies. The more unpredictable the business environment is, the less likely it will be a competitive location.

A: Our two biggest cost drivers are regulations and taxes. More than 2/3 of small and medium manufacturers are structured as pass through entities paying taxes at the individual rate. ACE is a sub-chapter S company. As a California manufacturer I know first-hand our regulations are challenging, time consuming, complex, redundant and change a lot. A new study released by the NAM estimates that regulations cost businesses $2 trillion annually and manufacturers face a disproportionate share – especially small and medium manufacturers because we don’t have the economies of scale. Our regulatory compliance costs at ACE are more than $9,000.00 per employee. We work in a highly regulated industry and it needs to be… lives depend on what we do. We make flight critical hardware. But we need a common sense approach with an improved and transparent process, independent economic analysis for potential impact and unintended consequences and sunset review for out of date, ineffective regulations that don’t live up to their promises . Because right now we find ourselves stuck between the rock of crushing economic circumstances and the hard place of inflexible bureaucratic regulations.

A: For us to stay competitive we must continually invest in our people, capabilities and our facilities. Our economic challenges and many factors in the global economy are forcing US manufacturer’s to seek new and more creative ways to innovate, achieve breakthrough gains in productivity and exceed customer’s expectations. We are way past the industrial age and the digital age is transforming how we solve complex problems. As business leaders we must look beyond the next quarter and into the next quarter century because those next twenty five years are rushing at us at the speed of light.

A: Talent will determine if we can compete and win. As a small manufacturer people truly are our greatest asset and our competitive advantage.

A: Our biggest challenge, long before the recession has been finding the skills and talent that we need at all levels in the organization to compete and win in the global economy. Our society has created a culture where everyone is expected to go to college.The skills we need don’t require a 4 year degree but do require more than a high school diploma. Contributing to the skills gap is the negative perception that many people have of manufacturing. Most don’t think we make things here anymore or have an outdated image of manufacturing. I think most people would be surprised to see how technology has transformed our factories and I think it’s important for them to see manufacturing in action.

A: At ACE we are getting our stories out there through videos and social media. We are developing educational partners, sponsoring robotics teams, donating equipment, hosting factory tours, providing internships and participating in Manufacturing Day. We are developing solutions targeted at improving company processes, driving innovation and transferring knowledge for an innovative focused manufacturing sector. Animation, computer graphics, augmented reality are all useful tools to push the envelope of creativity and innovation in a manufacturing environment. My goal is to dispel the notion that animation is used only for entertainment and cartoons. At ACE we are using animation software to create virtual factories, immersive learning tools and digital recreations of complex manufacturing processes. With a multi-cultural workforce visual tools provide a universal language for training and by promoting animation as a viable training solution we are enabling new career opportunities for animators. We are taking advantage of the powerful visualization capabilities and the creative potential of animation to preserve knowledge of the past while creating and exciting future for generations of manufacturer’s to come.

Q:Look in Your Crystal Ball, What is the Future of Manufacturing?A: This is manufacturing’s moment and the future is now! I am very excited about the intersection of manufacturing and technology. We are a traditional manufacturer implementing disruptive technologies in our processes and it is transforming the landscape of our industry. In this transformation, sensors, machines, work pieces, IT systems will be connected. These cyber physical systems will make it possible to gather and analyze data across machines, enabling faster, more flexible and more efficient processes to produce higher quality goods at reduced costs. This in turn will increase manufacturing productivity, shift economies, foster industrial growth, modify the profile of the workforce and ultimately change the competitiveness of companies and regions. Right now we have an opportunity to define our own success and blaze our own trail.