-

HYDROFORMING

Hydroforming was developed in the late 1940’s and early 1950’s. It provides a

-

HYDRAULIC PRESS

ACE purchased Honeywell’s metal forming division, and installed the equipment

-

-

DROP HAMMER

ACE boasts the largest drop hammer facility in North America. Our remarkable

-

-

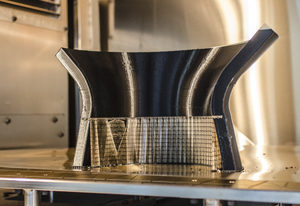

ADDITIVE MANUFACTURING

Additive manufacturing was remarkable from the very beginning. ACE knew it would have

-

5-AXIS LASER CUTTING

Double click to enlarge to full screen ACE has the advantage of a 5-axis, 3-dimensional CO2 laser cutting system which trims

-

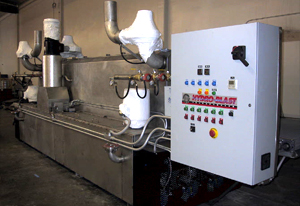

CLEAN LINE

Vital to our process is the continuous refreshing of the surface of parts, while in the process of being made. Every metal has some kind of oxidization process, and dust – ambient in any environment – or residue lubricants from our…

-

IN-PROCESS INSPECTION

In-process Inspections are also key to our production success. Inspections between work centers are scheduled and our inspectors use certified-calibrated gages and measurement tools to insure each part is perfect. Great lengths are taken to insure exact measurements and…