Manufacturability Proved the be the Winning Approach.

PRODUCT OVERVIEW

- Original design featured too many components

- 3D printing provided hands-on evaluation

- Custom tools simplified assembly and welding

- ACE in-house capabilities sped manufacturing process

- Time to manufacture cut in half

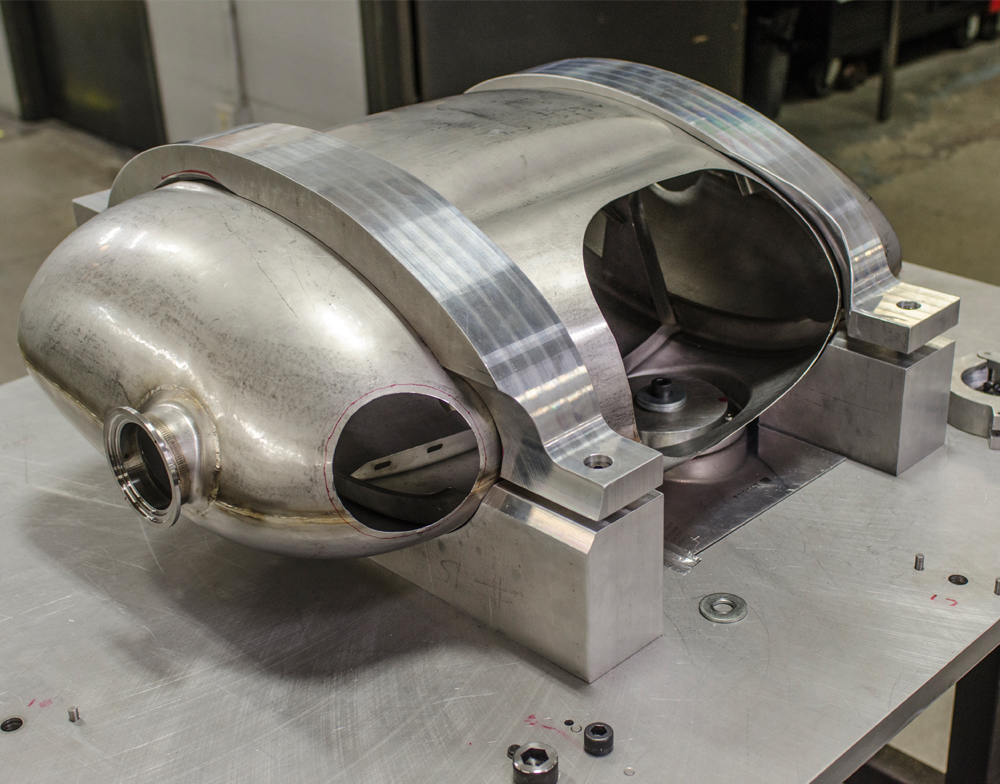

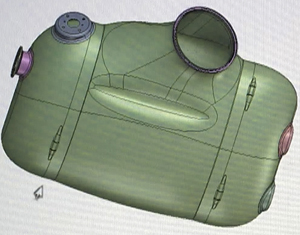

The Snowline story is a perfect example of ACE’s manufacturing expertise. Our customer, Snowline, had a pre-existing design for a sump tank with a detailed and complex inner structure. However, the many individual surface parts and multiple weld joints made the tanks very expensive to produce.

Utilizing our Fortus 3D Printer and Catia software, ACE manufacturing engineers worked with the Snowline engineers to simplify the tank into one-quarter of the individual pieces required to construct the original tank. The most dramatic improvement was drop hammering the two clamshell sides, which had been originally designed with 10 pieces, welded. Our solution of 2 halves dramatically cut production time and difficulty.

Once approved, we found we were able to turn around these tanks in half the time they originally required, with cost efficiency, increased strength and improved quality.