42 Days to Make the Launch. Wasn’t Even Close.

PRODUCT OVERVIEW

- Honeywell re-engineered the CO2 scrubbing devices needed

- ACE stepped up and did a full-court press on the production

- Incredible accuracy and speed were paramount

- Difficult metals, materials, milled sections, joints – all assembled perfectly

- ACE made the launch, and helped keep our astronauts safe

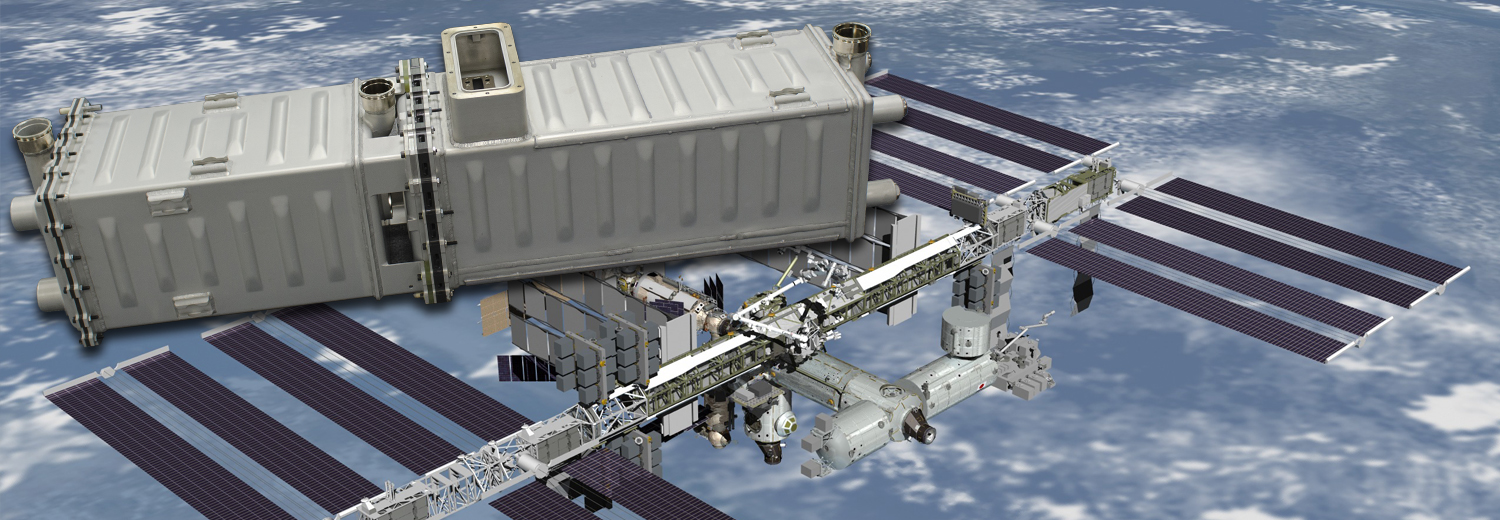

Honeywell came to ACE with a huge problem. The Carbon Dioxide Removal Assemblies (CDRA) were failing in the International Space Station. Three were down, and NASA only had three left. Plus, there were only 42 days before the next launch window.

CARBON DIOXIDE “SCRUBBERS” FOR THE INT’L SPACE STATION

Carbon Dioxide, what we exhale, can be very dangerous to humans who are off-world in a sealed environment. Usually this unbreathable gas is collected and expelled from the ship. However, for long-term occupancy, this closed-loop CDRA “scrubbing” system removed CO2 and restored oxygen from it, enabling its recycling. And that significantly reduced the amount of breathable air that has to be delivered periodically to the station in tanks from the surface. [In NASA “speak”: a 4-Bed Molecular Sieve Air Revitalization System, consisting of a desiccant (drying) bed and an absorbent bed (zeolite)]

WHAT WENT WRONG

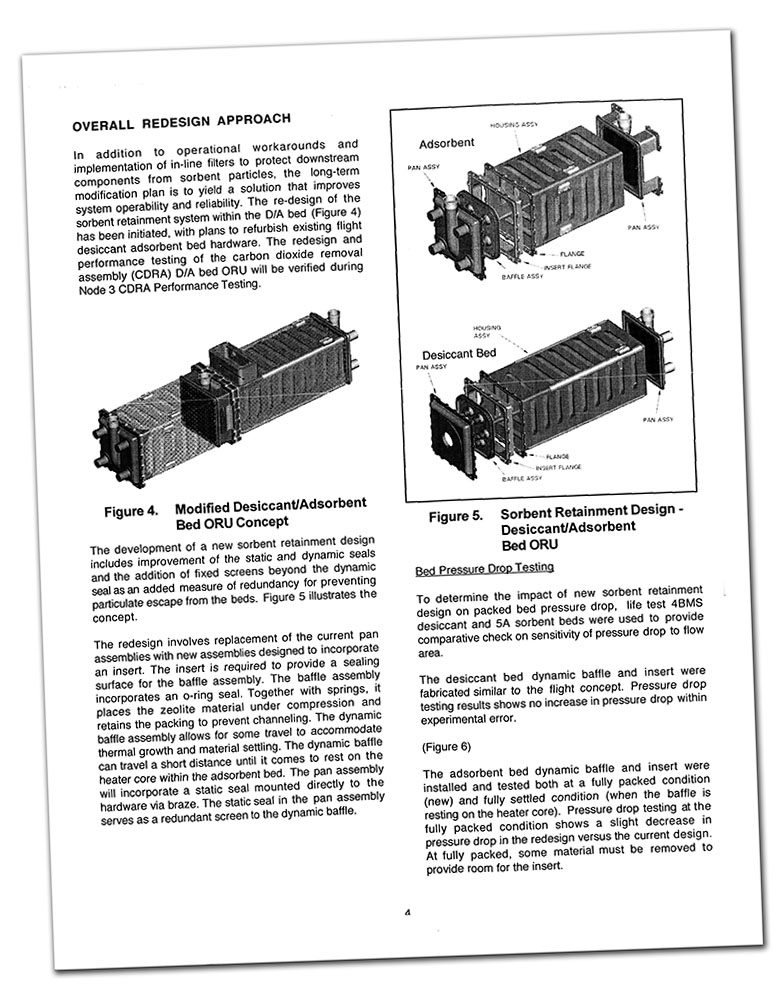

A bed of dust-sized particles of Zeolite are contained within the units — reactants to CO2. The Zeolite performs the process of subtracting the carbon from it. However, due to faulty seals, some of the particulates were circulating with the movement of process air and trailing out of the CDRA to other vital “downstream” components — resulting in malfunctions, as with the Air-Save Pumps.

A Honeywell redesign was implemented to correct the problems and ACE’s teams set to work. The outer casing sections were created with titanium, in sections, on our drop hammers. They were transported to ACE’s Torrance work centers and joined by other milled components for assembly.

The inner chambers and end caps were carved from pure stainless steel on our CNC’s. The outer housings and endcaps were fine-tuned by our deburr team. Precise seal connections were manufacturered in the machine shop. All components were set inside a custom fixture to hold them in precise place for ACE’s welders. Special filters were also created for the interior to minimize the escape of the Zeolite.

The CDRA is a vital component to the life support equipment in the air revitalization system of the ISS. ACE was honored to have been part of this exciting and very rewarding replacement operation, and look forward to the production of future equipment and components needed for space exploration.

For a great 3D rendering of the Space Station, go here http://www.boeing.com/space/international-space-station/#/hotspot/start3D

The following is a great tour of the space station by NASA Astronaut Steve Swanson, Expedition 39 Flight Engineer. At 33:40 into the video, he enters the Japanese Laboratory compartment where the CDRA are housed.

Double click to enlarge to full screen