-

Case Study: KC-135 Air Warming Exchangers

This highly complex air distribution duct is a great demonstration of the capabilities at ACE. It required many technical innovations in order to be manufactured. The base metal of these units is aluminum. That requires a highly skilled TIG welder who joins the pieces with the corrected amount of filler metal…

-

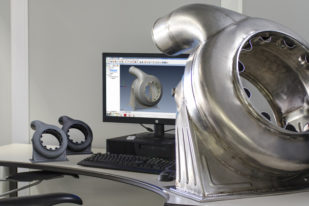

Case Study: GE POWER Generation Gas Turbine Transition Ducts & Impingement Sleeves

Power is the key word for these massive transition ducts and impingement sleeves, which channel huge amounts of superheated, compressed air from large combustion chamber…

-

Case Study: SNOWLINE Low Pressure Sump Tanks

The Snowline story is a perfect example of ACE’s manufacturing expertise. Our customer, Snowline, had a pre-existing design for a sump tank with a detailed and complex inner structure. However, the many individual surface parts and multiple weld joints made the tanks…

-

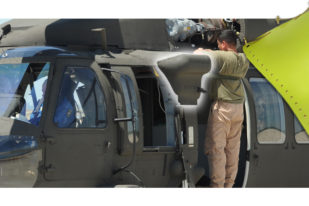

Case Study: SIKORSKY UH-60 Equipment Shield

The Sikorsky Black Hawk is the primary medium-lift helicopter for the U.S. Army. They perform a wide range of missions that encompass Air Assault, MEDEVAC, CSAR, Command and Control, and VIP transport. The newest version of the Army’s premier combat utility helicopter…

-

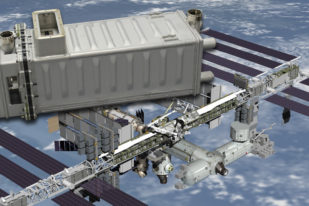

Case Study: HONEYWELL, NASA and the International Space Station

Honeywell came to ACE with a huge problem. The Carbon Dioxide Removal Assemblies (CDRA) were failing in the International Space Station. Three were down, and NASA only had three left. Plus, there were only…

-

Case Study: LOCKHEED MARTIN F-22 APU Intakes

This very sophisticated design was a manufacturing challenge. Made from high-grade aluminum, the original design was soon discovered to react to air pressures at speeds above Mach 1, when the force of the air and the location of the vents created…

-

Case Study: HONEYWELL for the Recommissioned B-52H’s

The original design for the B-52 Bomber Oil Cooling system was invented more than 60 years ago. Now that the aircraft are being re-commissioned, replacements had to be created. ACE was chosen because of our…

-

Case Study: HONEYWELL Air Cooling Device

The Boeing 777 relies on just two wing engines to provide thrust for flight. Thus, in its development, engineers determined that no other power should be bled off them for system hydraulics, and designed a space in its tail for a third, auxiliary gas turbine engine…

-

Case Study: SAFRAN CENCO Jet Engine Test Platform Pylon

Aircraft engines must be continually tested during development to determine balance, thrust, vibration and durability of the designs. Testing facilities rely on huge structures, or armatures, which hold these massive engines in place at full throttle…